Accurate and Reliable Burst Pressure Analysis for Better Decision-Making

Creaform's burst pressure simulations generate 3D visual reports of the digitized surface. They calculate stress and strain to evaluate burst pressure and its location, using the triaxial strain criteria of API-579. This allows asset owners and service companies to clearly visualize the constraints and limits on their operating pipelines.

Stress, strains, and triaxiality criteria

Maximum burst pressure based on triaxiality criteria

How the Service Works

Export a precise model of your damaged pipeline with one click

Transfer data through safe cloud services

Receive simulation analysis compatible with VXintegrity for optimal visualization

Continue operating safely with the highest assessment level

Avoid costly repairs and prevent unnecessary production stoppages

Burst Pressure Simulations Made Accessible for Routine Inspections

Historically, Level III assessments were complex and required considerable time and expertise. Now, with its new service, Creaform Engineering significantly reduces the time and effort needed to achieve this level of compliance.

Level III assessment completed in days, not weeks

FEA simulations completed at a fraction of the cost

Reduced process complexity, no project manager needed

Possibility to standardize the process for compliance

Simulation Package Available

Request more information

Optimize preventive maintenance plans with results closest to real data

Make better decisions based on accurate and reliable simulations

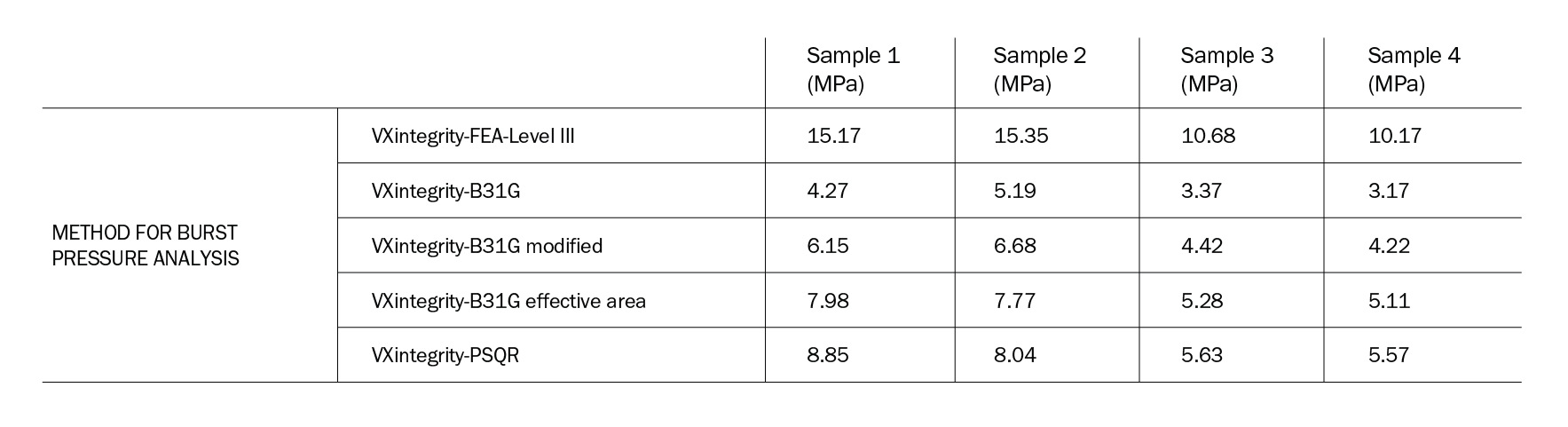

FEA Simulation vs. Pipeline Results

Level III assessment, less conservative than other standards, allows for more permissive rates.

FEA simulations provide more accurate burst pressure measurements compared to conservative standard calculations, allowing asset owners to secure more permissive rates (up to 2.5X higher) and optimize preventive maintenance.

Creaform 3D Scanning Technology

3D Scanning Solutions for Surface Damage Assessment