Challenge: Rapid Development of a Custom Heavy Loader

When Rotobec received a custom request for a trailer-mounted diesel loader for delimbing and loading wood, they faced a significant challenge. This machine was outside their standard product line, and with tight deadlines, there was no room for costly prototyping, creating an urgent need for innovation.

To meet their client’s expectations without compromising quality, Rotobec turned to Creaform Engineering for expertise in structural design and advanced validation methods, particularly Finite Element Analysis (FEA).

The Solution: Leveraging FEA for Precision and Speed

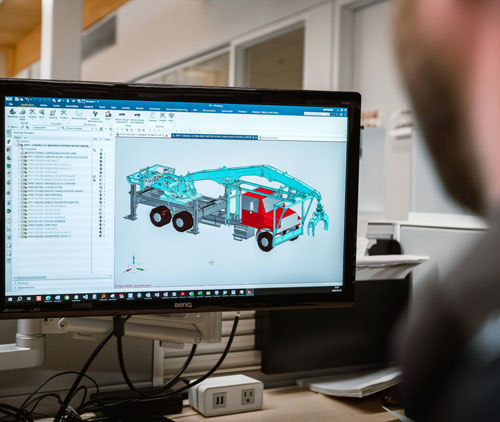

Our team was responsible for designing the loader’s structural components including the stick boom, main boom, and base with stabilizers, all crucial for durability and efficiency. The primary challenge was to ensure a fully functional design while quickly validating its structural integrity without resorting to costly prototyping.

Leveraging FEA, our experts simulated the behavior of these components under heavy loads, identifying high-stress areas and optimizing the design for reliability in the field. Through detailed numerical simulations, we provided Rotobec with insights into the loader’s performance under various conditions, allowing us to fine-tune the design to meet safety and performance standards while significantly reducing prototyping time and costs.

Results: A Reliable Solution Delivered on Time

Through close collaboration and Creaform Engineering’s expertise in FEA, we helped deliver a custom-engineered machine that exceeded expectations. Our FEA-based validation ensured the structural components met high-quality standards, allowing Rotobec to focus on other aspects of design and manufacturing with confidence in the machine’s reliability.

Key Results:

- Faster Time-to-Market: Streamlined design process without the need for costly prototypes.

- Enhanced Structural Integrity: FEA validation ensured durability and performance, even in tough conditions.

- Client Satisfaction: The end-user praised the machine’s reliability, reinforcing Rotobec’s industry leadership.

Learn how this custom solution came together – read the full story and watch the video to see how this project can inspire your own innovations.

Services provided

- Mechanical design, including structures, hydraulic rooting, mechanisms, etc.

- 3D and 2D CAD drawings, including general assembly drawings (NX)

- Lift capacity analysis and optimization of geometry using an analytic approach

- Preliminary analysis and structural recommendations prior to design

- Finite Element Model using strict standards (Nastran)

- Static linear and non-linear analysis

- Fatigue life evaluation

- Factor of safety calculations for metallic and interface joints (fastners, pins)

- Results presentation and detailed report

- Manufacturing liaison

TOOLS AND METHODS USED

- Femap

- Nastran

- NX

Need help with a similar project?

Creaform has a breadth of services that cater to the unique and stringent needs in the heavy industry. Speak to our experts today to see how we can complement your next project.