THE PROJECT

Creaform Engineering was tasked with developing equipment aimed at automating the packaging step of a production line.

The customer, operating in the consumer goods industry, wanted to eliminate manual tasks revolving around the removal of packages from a machine. This task proved to be strenuous, repetitive and quite detrimental to the workers’ health and safety.

The key obstacle to a successful integration was that the development, manufacturing, off-the-line testing and on-the-line installation of the equipment had to be done within a short timeframe.

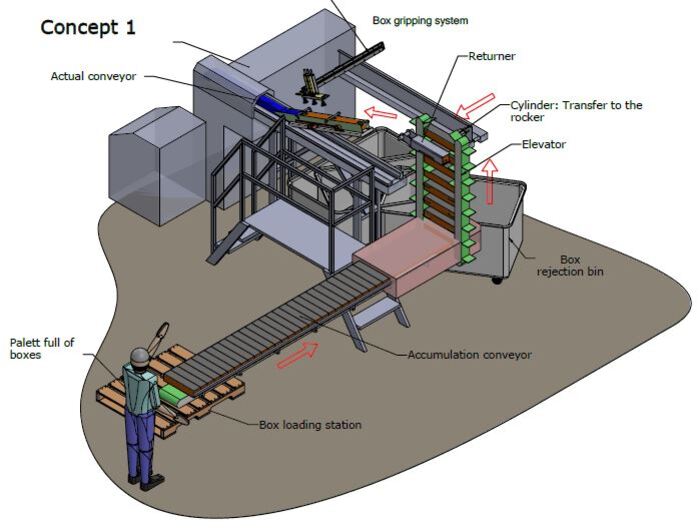

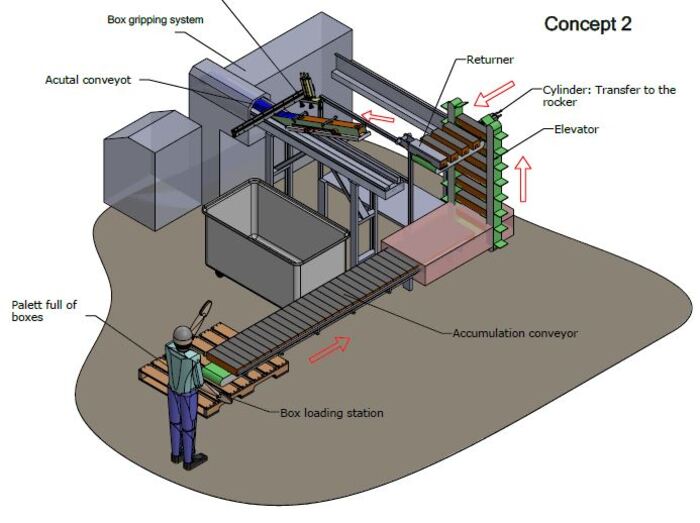

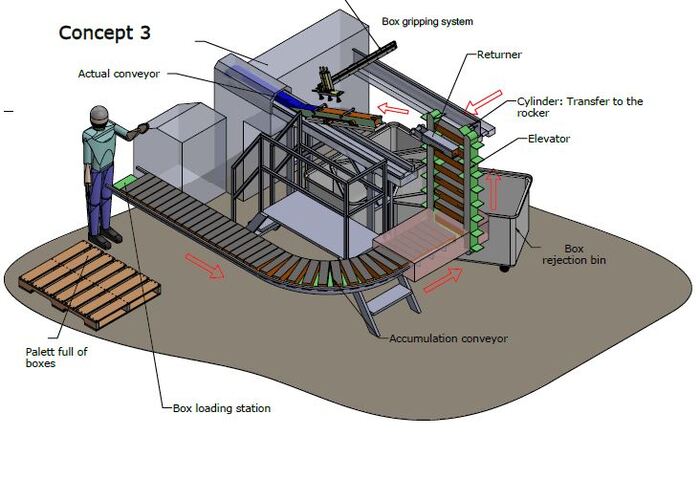

First, Creaform Engineering submitted four equipment layouts, each with their benefits, downsides and criteria in terms of footprint, machine reliability, total cost of ownership, and operator care, maintenance and autonomy.

Subsequently, the project was awarded to the Creaform Engineering team, tasked with developing custom equipment to ensure the safety, reliability, and repeatability of the system. The integration of this equipment was highly successful and completed within the set timeframe.

The result? An automated set of subprocesses that reduces repetitive manual labor, freeing skilled workers for value-added tasks.

SERVICES RENDERED

- Mechanical and Electrical Design

- Mechanical and Electrical Engineering

- Machine Safety (CMSE®)

- Risk Analysis

- Procurement

- Electrical Certification

- Machine Design and Custom Tooling Development

- Monitoring for Manufacturing, Assembly and On-Site Installation

- Project Management

Need help with a similar project?

Creaform Engineering has a breadth of services that cater to the unique and stringent needs in the transportation industry. Speak to our experts today to see how we can complement your next project.