Challenge: Capturing Complex Blast Dynamics

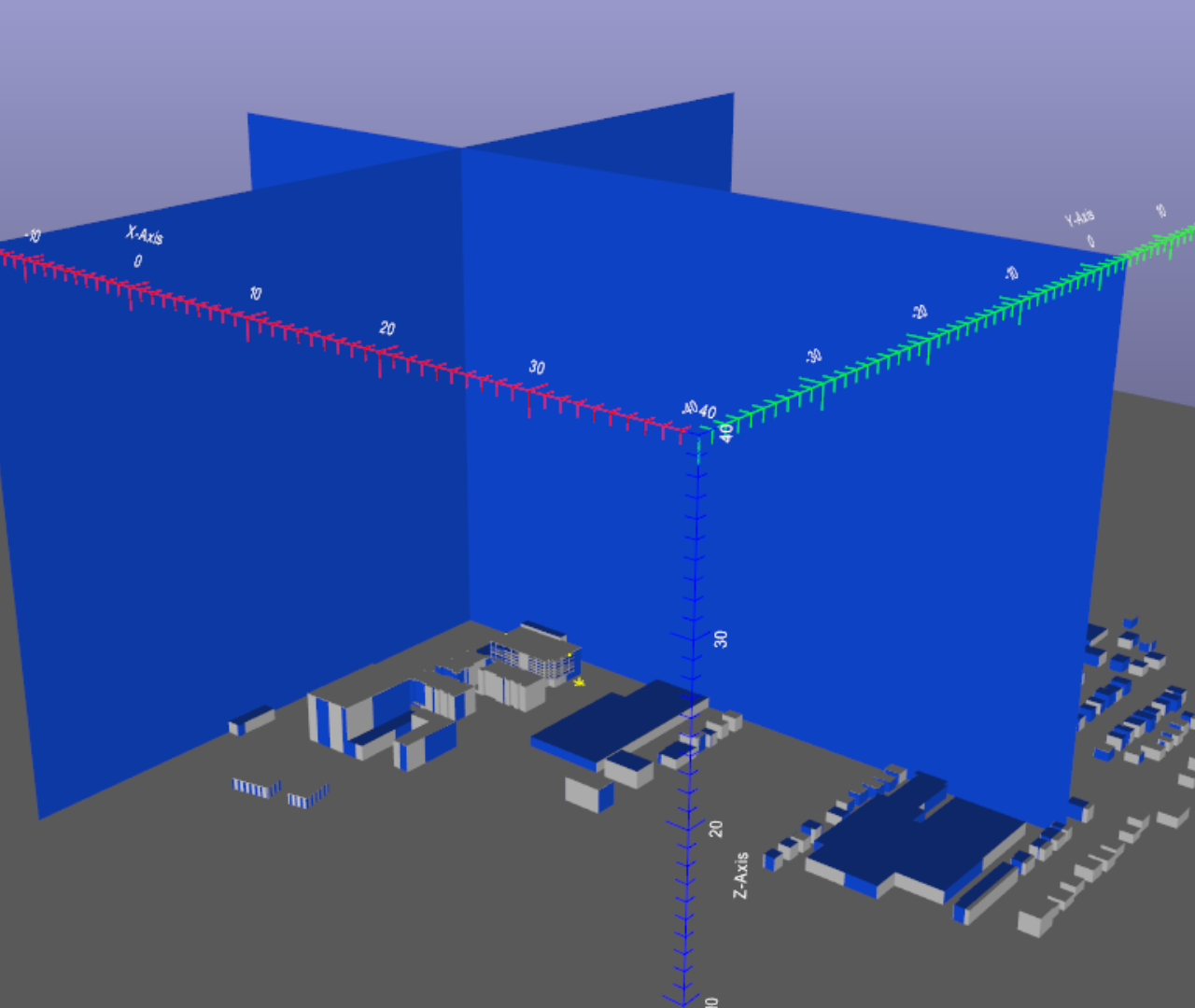

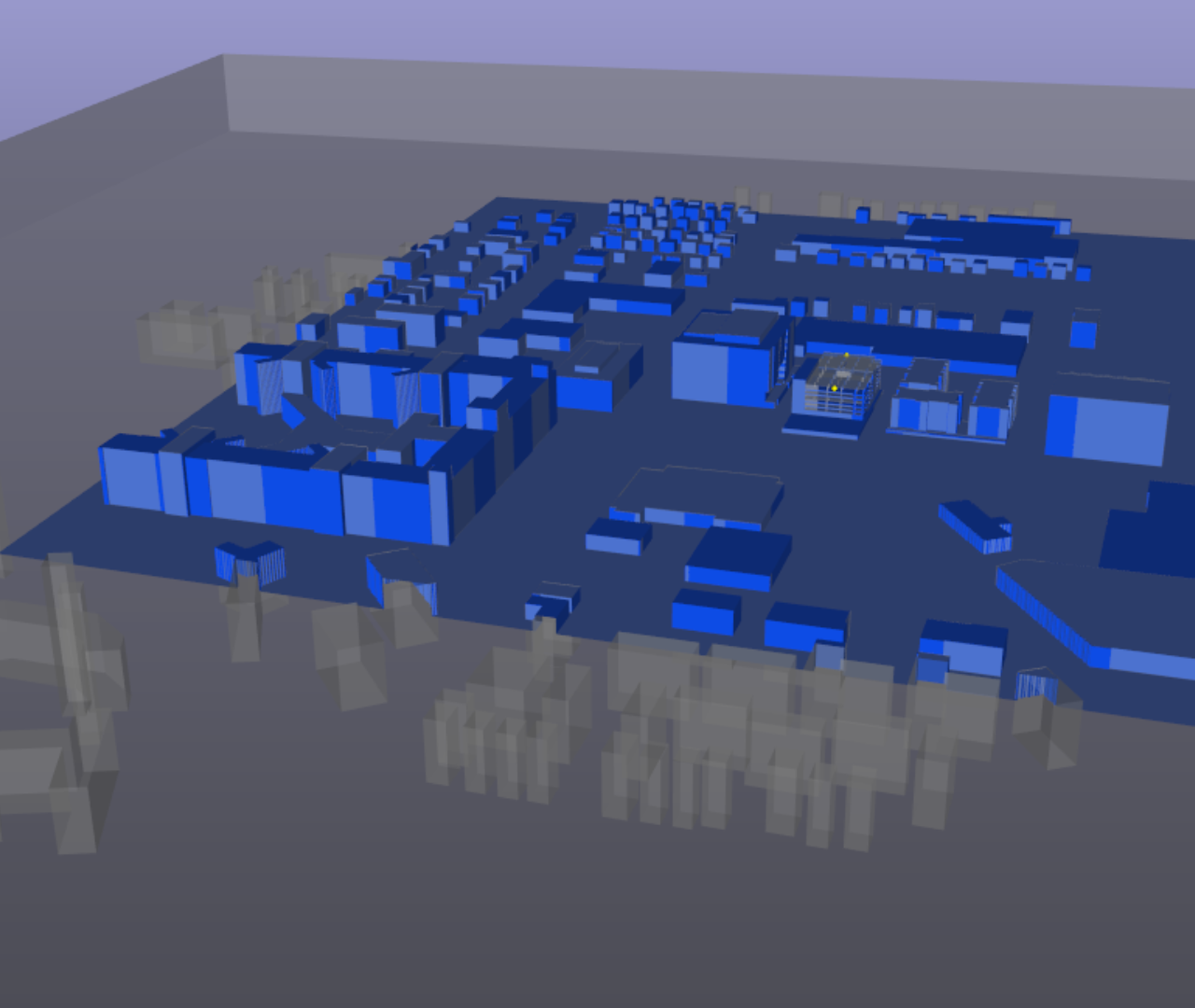

To support the design of blast-resistant urban infrastructure, Creaform Engineering conducted a high-fidelity CFD simulation of an urban blast scenario. For an undisclosed customer project, the objective was to evaluate peak overpressure propagation and material flow dynamics in a complex city-like environment.

Blast simulations require precise modeling to capture transient phenomena such as peak overpressure at multiple locations, shockwave reflections, and material displacement. The challenge lies in accurately representing urban geometry, ensuring mesh quality in confined spaces, and solving highly nonlinear flow equations under extreme conditions, all while maintaining computational efficiency.

Solution: High-Fidelity Modeling at Work

Creaform Engineering leveraged its advanced numerical simulation capabilities to meet the demands of high-fidelity blast modeling:

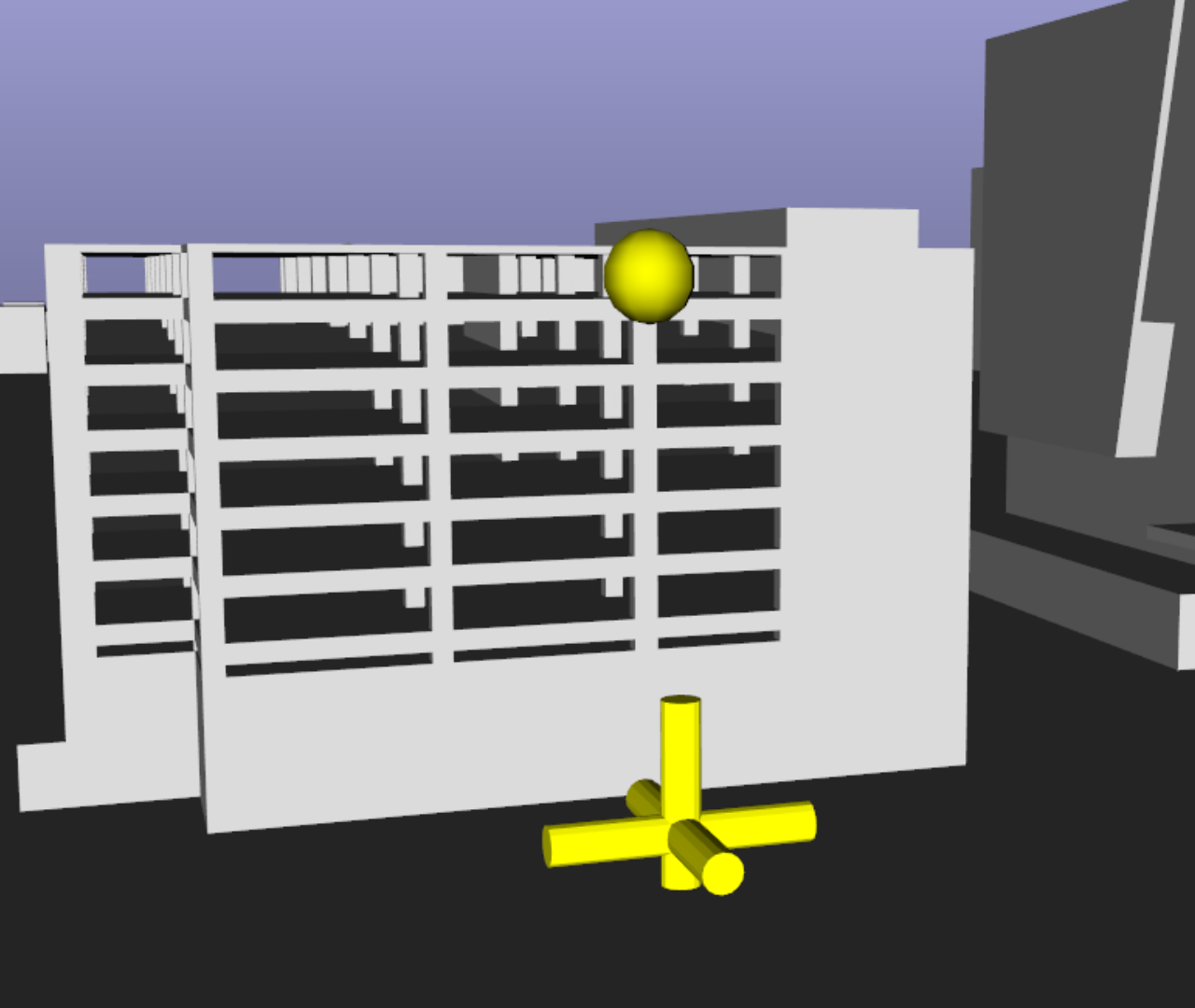

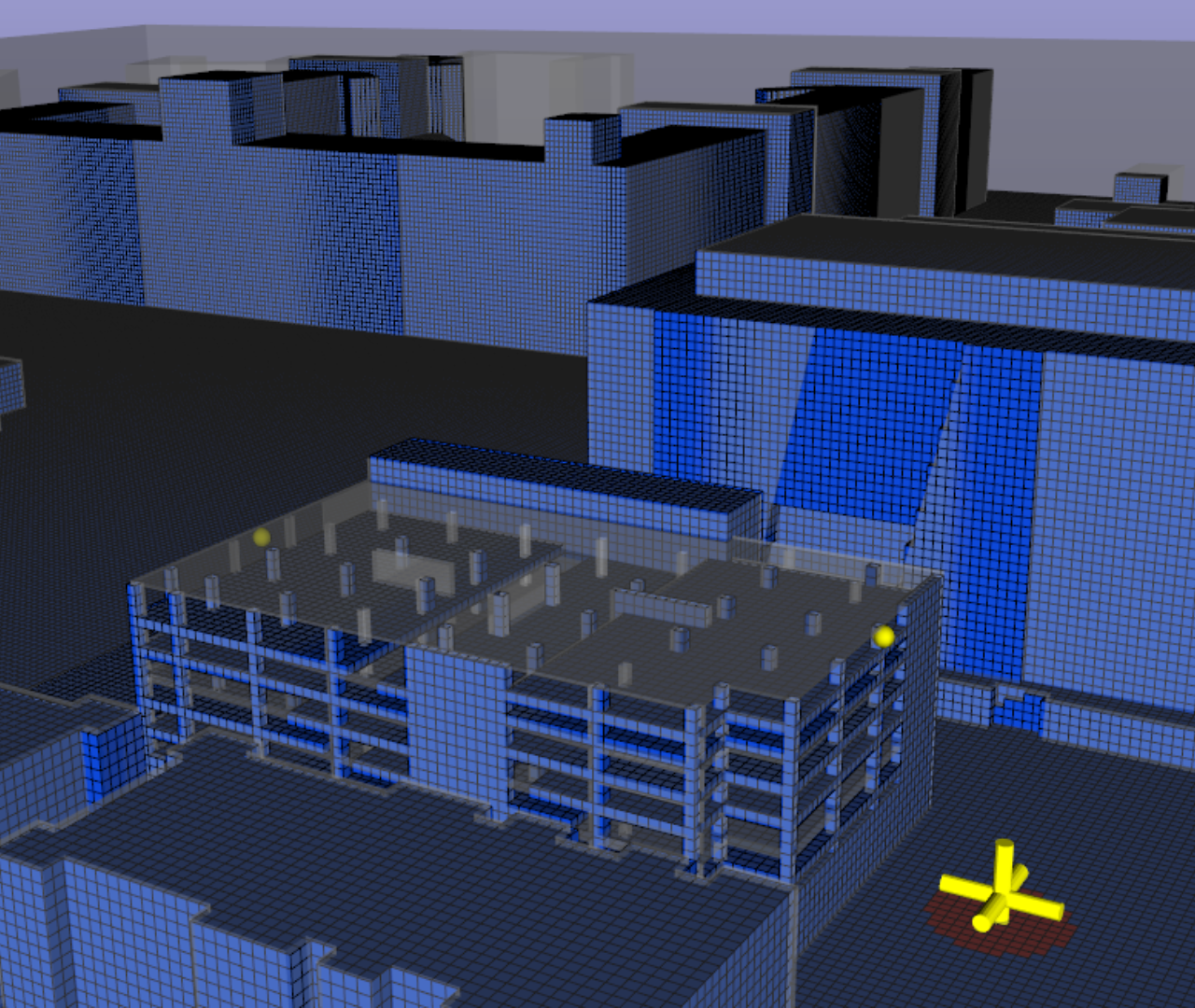

Detailed geometry handling to accurately represent urban structures and their influence on blast propagation.

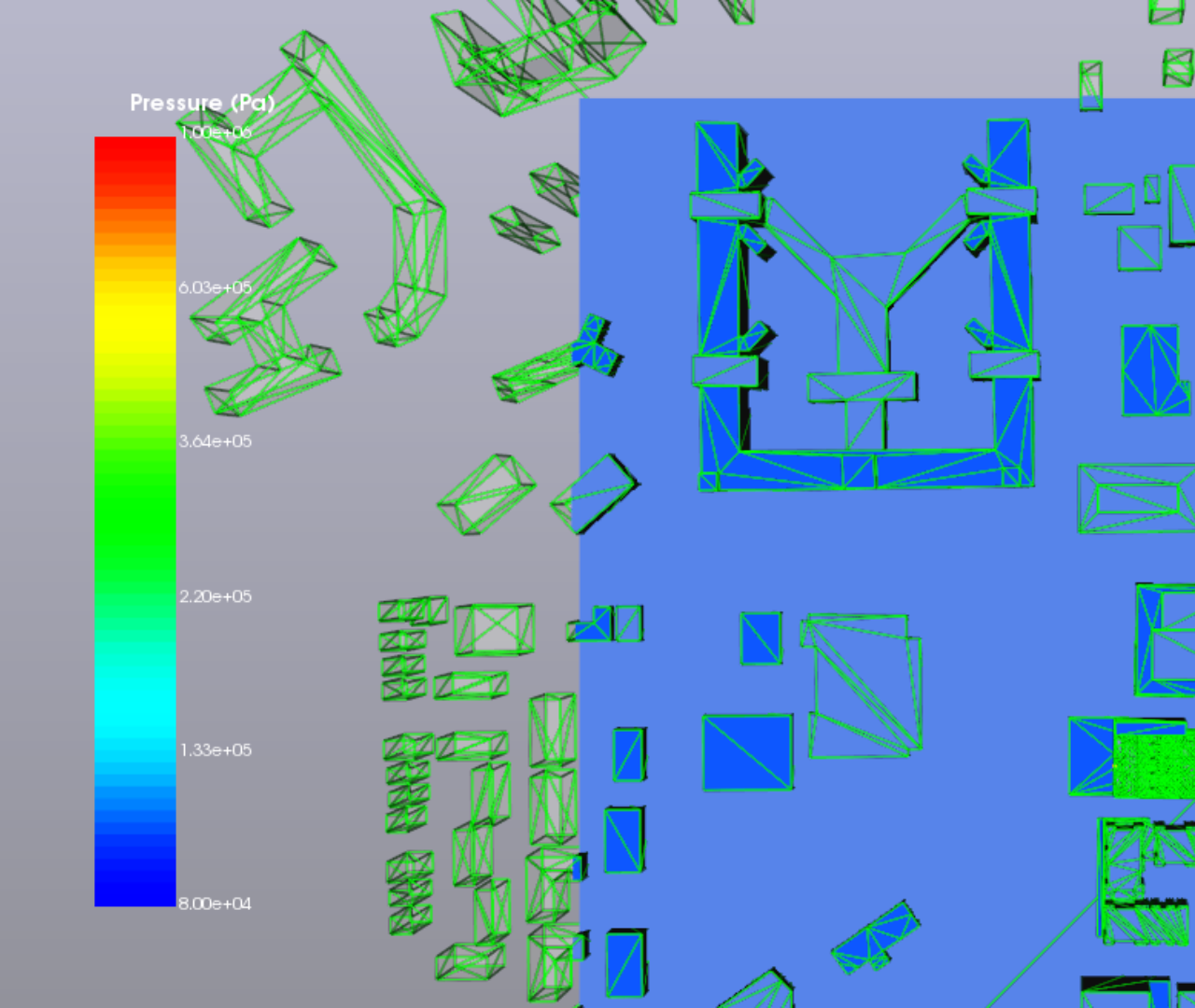

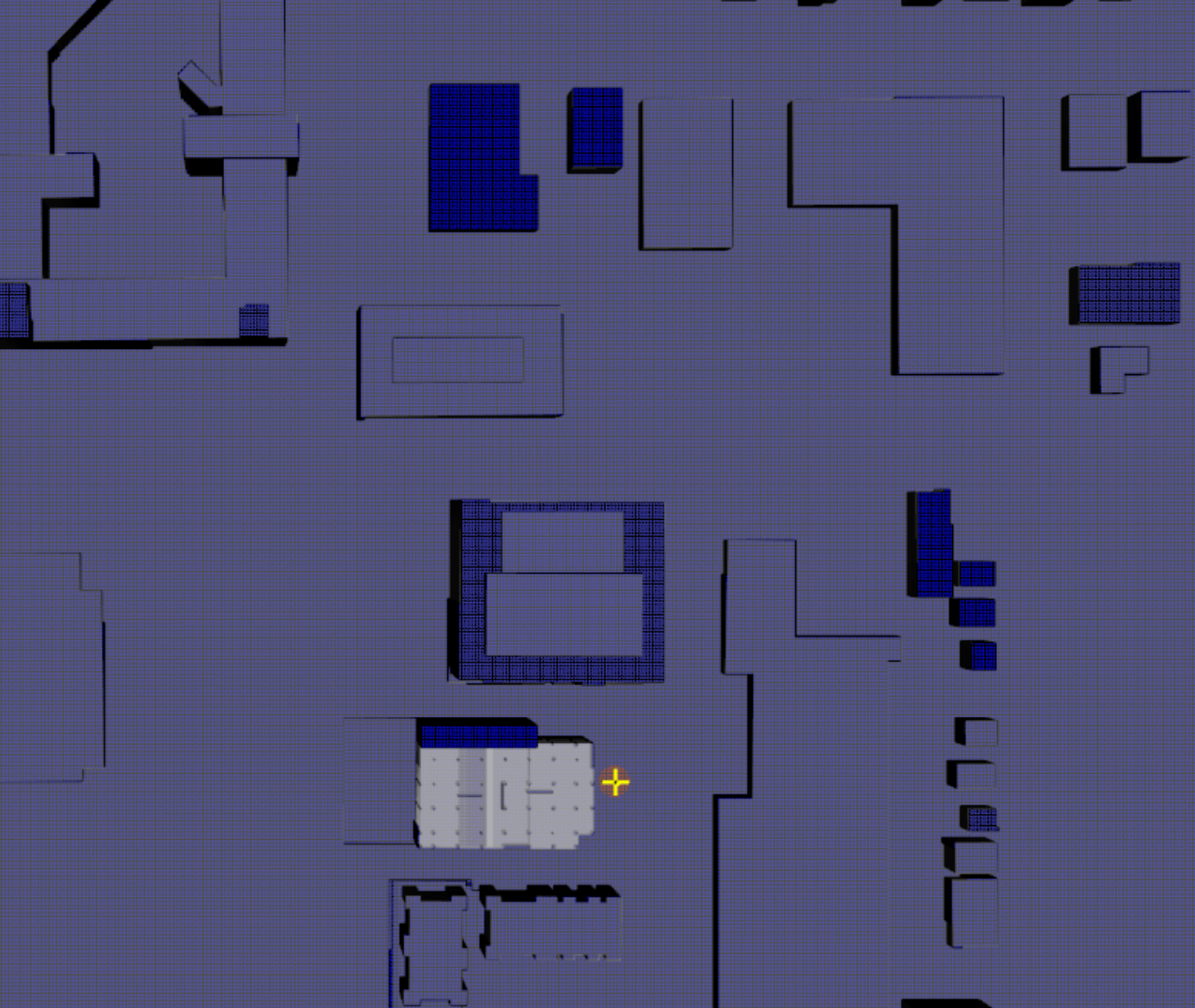

High-quality volume meshing to resolve shockwave interactions and flow gradients in complex environments.

GPU-based solvers to accelerate computation and enable high-resolution simulations within practical timeframes.

CFD and FEA coupling to bridge fluid dynamics and structural mechanics, allowing the pressure signal from the blast to be mapped directly onto structural surfaces. This enabled precise evaluation of stress and strain responses in critical components, supporting the design of blast-resistant infrastructure.

The simulation visualized both the evolving peak overpressure map and tracer particles, offering insight into the flow of material away from the blast origin and the dynamic interaction with surrounding structures.

Results: Insight for Safer Design

The simulation provided critical data for evaluating blast impact zones and designing mitigation measures. By capturing peak overpressure with high spatial accuracy and coupling it with structural analysis, Creaform Engineering enabled its client to:

Identify high-risk areas within the urban layout.

Quantify stress and strain on key structural elements under realistic blast loading.

Refine structural designs for improved blast resistance.

Reduce development time and cost through predictive modeling and virtual testing.

This project highlights Creaform Engineering’s growing expertise in blast simulation across sectors such as defense, aerospace, oil & gas, mining, and civil infrastructure—where safety and resilience are paramount.

Services provided

3D Model Preparation: Accurate reconstruction of urban geometry from CAD or GIS data, ensuring realistic interaction between blast waves and structures.

Volume Meshing: Generation of high-quality, shock-resolving meshes tailored for transient blast dynamics in complex environments.

Material Characterization: Definition of material properties for air, structural components, and debris, including nonlinear and rate-dependent behavior.

GPU-Based CFD Solving:High-performance computing using GPU acceleration to simulate blast propagation and flow dynamics efficiently.

CFD/FEA Coupling: Integration of fluid and structural solvers to map pressure signals onto surfaces and evaluate stress, strain, and potential failure zones.

Blast Load Mapping: Extraction of peak overpressure and impulse data at critical locations for structural assessment.

Design Recommendations: Engineering insights to improve blast resistance, including layout optimization and material selection.

Optimization Studies:Parametric simulations to explore design alternatives and enhance safety and performance under blast scenarios.

Visualization & Reporting: Generation of high-impact visuals (e.g., pressure maps, tracer particle animations) and detailed technical reports for stakeholders.