Cockpit ejection is a last-resort decision made in high-stakes scenarios, requiring a mix of instinct, intense training, and immediate situational awareness from the pilot.

One thing is clear: when this rare and critical moment arrives, the pilot's survival hinges entirely on whether every piece of equipment has been meticulously developed, rigorously tested, and is flawlessly functioning to protect life in the face of imminent danger.

This is exactly the mission that Lortie Aviation entrusted to Creaform Engineering: minimizing injuries during emergency seat ejections. In the initial phases of the project, the engineering team developed and incorporated a crushable pad into the seat, reducing the energy transmitted to the pilot’s pelvis and significantly decreasing the acceleration peaks experienced during ejection.

Then, Creaform Engineering continued its development efforts, proposing an additional solution to further enhance spine protection. However, this approach introduced a potential risk of clavicle injuries, which was not ideal for Lortie Aviation. To address this, Creaform Engineering collaborated with TOPMED, a biomedical engineering center, to integrate a new component into the harness, effectively reducing the risk of clavicle injury.

Lortie Aviation Pilots’ Request: Taking the Mandate to New Heights

Lortie Aviation owns a fleet of Hawker Hunter fighters, which were designed in the 1950s and used in combat until 2014. This transonic aircraft is equipped with Martin-Baker MK3 ejection seats, which involves that reverse engineering and replacing them with a newer, safer seat is not feasible due to the plane's small size and the impracticality of retrofitting.

After integrating a crushable honeycomb pad into the Martin-Baker ejection seat to reduce impulse, peak pelvis acceleration, and lumbar loads (link to the previous article), Creaform Engineering consulted with Lortie Aviation pilots to gather their feedback.

Simply put, Lortie Aviation wanted more and requested the mandate to be extended with the following objectives:

1. to reproduce the vertebral injuries using a finite element model

2. to demonstrate the impact of mitigation on vertebral compression.

Without delay, the team of numerical simulation experts took action

Ejection Simulation with the THUMS Bio-Fidelic Finite Element Model

To better represent the mechanical behavior of the spine and potential vertebral injuries, Creaform Engineering utilized the THUMS, a highly detailed, bio-fidelic finite element model of the human body. Standing for Total Human Model for Safety, the THUMS was initially developed by Toyota in collaboration with research institutions and is widely used today across industries to evaluate the effects of impacts on the human body and to design safety measures that minimize injuries.Using this bio-fidelic finite element model, the engineers simulated the ejection to analyze the sequence leading to vertebral compression. This approach allowed them to assess whether the mitigation measures effectively reduced the risk of spinal injury and evaluate the performance of the crushable pad.

Simulation Findings: Vertebral Compression Not Prevented by the Crushable Pad

The simulations showed that the crushable pad deformed quickly, partly absorbing kinetic energy. However, it was found that vertebral compression is induced at a later stage. Following the sequence of events during the pilot's ejection, the rib cage rolls forward, compressing the vertebrae. Because the crushable pad compresses upon ejection and its impact on the upper body is not instantaneous, it does not effectively reduce the risk of vertebral injury.

However, the bio-fidelic finite element model highlighted the importance of pilot posture during ejection. When the pilot maintains an upright posture with the harness tightly fastened to the seat, the rotation of the rib cage is reduced, minimizing spinal compression and lowering the risk of vertebral injury.

This conclusion led to a new recommendation: increasing harness pretension to keep the spine straight during ejection.

Improved Spine Protection with Increased Harness Pretension

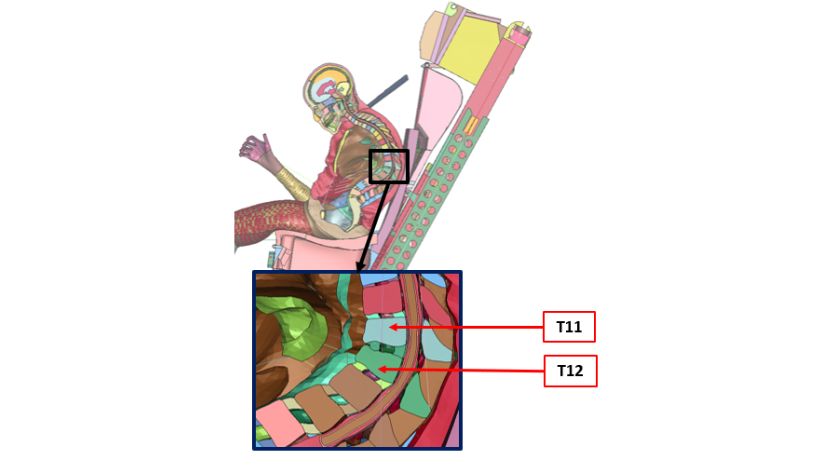

Numerical simulations conducted by Creaform Engineering demonstrated that improving pilot posture during ejection—achieved through increased harness pretension—significantly reduced compression of the T11 and T12 vertebrae. Specifically, compression of the T11 vertebra decreased by 42%, dropping from 24% to 14%, while T12 compression was reduced by 73%, falling from 22% to 6%.Given the positive impact on pilot safety, implementing seatbelt retractors to increase harness pretension was recommended.

Higher Probability of Clavicle Fractures

However, the THUMS bio-fidelic finite element model also revealed a significant concern regarding the addition of seatbelt retractors. Although harness pretension reduces spinal compression, the force generated during ejection that triggers the seatbelt retractors may also increase the risk of clavicle fractures.Clavicle vs. Vertebrae

In this situation, pilots were understandably apprehensive about maneuvering with a broken clavicle. While their spines would remain intact, the prospect of landing in water and climbing onto a raft with a fractured clavicle was daunting. Avoiding such a scenario was preferable for them.

Therefore, how could harness pretension be maintained while mitigating the risk of clavicle fractures? This is where TOPMED came into play with an effective orthosis design.

Clavicle Protection with an Orthosis

To mitigate the risk of clavicle fractures, Creaform Engineering partnered with TOPMED, a health research and innovation center in Quebec City specialized in developing orthotic equipment. Their goal was to design an orthosis that better distributes the force exerted by seatbelt retractors during ejection, thereby protecting the clavicles.

To test the effectiveness of this protection, TOPMED also developed and 3D printed an instrumented torso equipped with force sensors to measure the compressive force applied on the clavicles. The objective was to show a significant reduction between the tests made with and without the protection, underlining the importance of this protection in reducing the risk of injury.

Correlating Numerical Simulations with Physical Tests

TOPMED developed a prototype orthosis consisting of a pouch filled with air cells. Testing the device was then crucial to validate its performance and durability. To do so, the orthosis was integrated into the seat harness using seatbelt retractors and fastening the instrumented torso to the ejection seat.

Harness pretension, triggered by the activation of seat retractors during ejection, was tested by applying an electric current to the retractors, which tightened the torso against the seat. This simulation was conducted with and without the orthosis in place, enabling the measurement of the force applied to the clavicles with and without the protection.

The test results revealed a significant reduction in the forces applied to the clavicles while wearing the protection, dropping from above 3500N (sensor saturation point) without the orthosis to below 500N with it.

These physical tests performed on the instrumented torso demonstrated the orthosis’s capability to effectively distribute harness pretension across the clavicle region, attesting the effectiveness of the design in mitigating the pressure exerted on the clavicles by the seatbelt retractors during ejection.

In short, Creaform Engineering, in collaboration with TOPMED, validated the mitigation strategy through physical testing. Although a problem was identified, the tests led to a solution that effectively mitigated the risk of injury.

Top-Flight Performance with Maximum Safety

Creaform Engineering conducted numerical simulations and physical tests to assess mitigation strategies for reducing the risk of vertebral injuries and clavicle fractures during fighter jet ejections.The THUMS, a highly detailed, bio-fidelic finite element model, was used to simulate the ejection and analyze the sequence leading to vertebral compression. It showed that increased harness pretension could significantly reduce T11 and T12 vertebrae compression.

But Creaform Engineering did not stop there. They collaborated with TOPMED to develop an orthosis that could offer notable protection during ejection. Physical tests then proved the orthosis’s capability to effectively redistribute the force exerted by seatbelt retractors, mitigating the risk of fractures that pilots wanted to avoid.

With the proof of concept successfully demonstrated, Lortie Aviation will now integrate the orthosis into the harness, ensuring pilots can perform maneuvers effectively. One thing is certain: from numerical simulations to physical tests, every piece of equipment has been meticulously designed, tested, and optimized to enable pilots to deliver top-flight performance at the highest level of safety.