In recent years, numerical simulation has become an essential part of the manufacturing process, allowing manufacturers to minimize the number of physical prototypes required, reduce development costs, and speed up time to market. By using simulation software and other computer-aided engineering (CAE) tools, engineers and designers can accurately predict how a product will perform in real-world conditions and make the necessary changes to improve its performance and efficiency before it is manufactured.

In this comprehensive guide, we explore what numerical simulation is and its benefits in engineering and product development, the different types of simulation methods, and provide examples of how simulation-driven design has been used in various industries. Whether you're a designer, engineer, or product manager, this guide will help you understand the importance of simulation-driven design and how to effectively implement it to create better products.

1. What is Numerical Simulation in Engineering Design?

Put simply, numerical simulation, also known as engineering simulation or virtual prototyping, is the process of creating virtual models of products or systems and then evaluating the performance of their design under various conditions and scenarios using specialized simulation software.

The goal of numerical simulation is to optimize the design of a product or system before it is physically built or manufactured by identifying potential design flaws and areas for improvement. It helps manufacturers determine whether the product meets particular design parameters and characteristics, including strength, safety, deterioration, expected lifespan, and other variables, to ensure optimum use. It also helps to verify and validate the product’s or system’s actual manufacturability and reduces development time and costs.

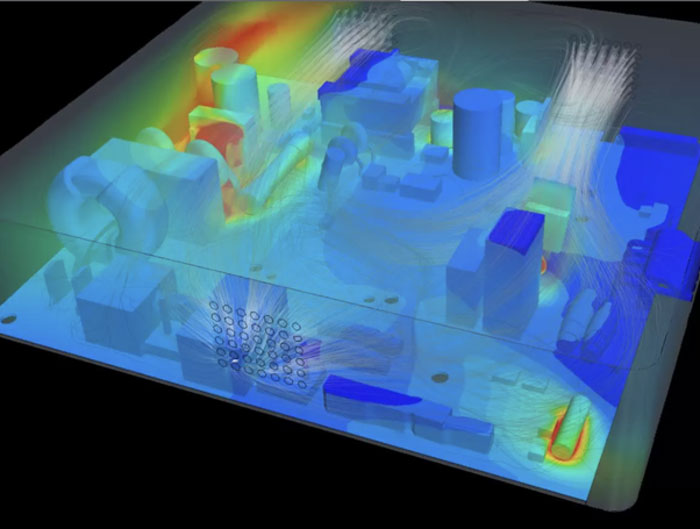

Source: https://creaform-engineering.com/en/portfolio-items/pcb-cooling-analysis/

Engineers and product designers use a variety of simulation methods to virtually test the behavior of a product or system under various operating and environmental conditions, including mechanical stresses and strains, fluid flow, emergency conditions such as extreme heat and cold, electromagnetic fields, acoustic noise, vibration, fatigue, and many other conditions.

Numerical simulation is used in a wide range of industries to optimize the design and performance of various products and systems. For instance, aircraft manufacturing and maintenance companies rely on numerical simulation to evaluate the stress and strain on the landing gear during landing and takeoff and to optimize the design to reduce the weight while maintaining its strength.

Automotive companies use crash simulations (among many others) to evaluate the safety of vehicles during crashes and optimize the design of safety features such as airbags, seat belts, and crumple zones.

The energy industry uses numerical simulation to optimize the design and performance of energy systems such as power plants, wind turbines, and solar panels. Sports companies use it to optimize the design and performance of sports equipment, such as baseball bats, golf clubs, and tennis rackets.

2. What are the main steps of a numerical simulation process?

The steps involved in conducting a simulation process may vary depending on the specific application and simulation method being used. However, here are some common steps involved in the simulation process:

Step 1. Problem definition

The first step is usually to define the problem to be solved and the objectives of the simulation. This includes identifying the system or process to be simulated, the inputs and outputs of the system, and the performance criteria that will be used to evaluate the simulation results.

Step 2. Model design

The next step is to design a mathematical model of the system or process to be simulated. This involves selecting the appropriate simulation method and developing a set of equations that describe the behavior of the system. The model should be validated to ensure that it accurately represents the real system or process.

Step 3. Defining inputs and boundary conditions

Then, the designed model requires a set of inputs and constraints to simulate the behavior of the system under different scenarios. This includes specifying the values of parameters such as temperature, pressure, and velocity, as well as defining the boundary conditions to which the system is subjected.

Step 4. Running the simulation

Once the model has been developed and the inputs and boundary conditions have been defined, the simulation can be performed. This involves solving the equations that describe the behavior of the system using numerical methods on a computer.

Step 5. Results analysis

Once the simulation is complete, the next step is to analyze the results and determine how the system or process behaves under different scenarios. This involves examining outputs such as stress, strain, temperature, and flow rates, and comparing the simulation results to the performance criteria defined in Step 1.

Step 6. Validating and refining the model

The final step is to validate the simulation results by comparing them to real-world data and refining the model as needed. This involves identifying any discrepancies between the simulation results and the real-world data, adjusting the model parameters or inputs, and re-running the simulation until the results are satisfactory.

Overall, the simulation process involves a series of iterative steps in which the model and simulation results are refined until they accurately represent the real-world system or process being analyzed.

3. What are the main types of simulation methods used in engineering design?

Depending on the product and application, numerical simulation can include different types of simulations, such as finite element analysis (FEA) simulation, computational fluid dynamics (CFD) simulation, discrete element method (DEM) simulation, and others. Let's take a closer look at some of the more common ones.

What is finite element analysis (FEA)?

Finite Element Analysis (FEA) is a numerical simulation method used to analyze the behavior of complex systems and structures under various conditions. FEA involves breaking down a complex system into smaller, simpler parts, or finite elements, and then analyzing and solving for the behavior of each element. By combining the behavior of all the individual elements, FEA can provide a detailed understanding of how the entire system will behave under different conditions. FEA is commonly used in mechanical and structural engineering to simulate the behavior of materials and structures under stress, heat transfer, and other conditions.

What is computational fluid dynamics (CFD)?

Computational Fluid Dynamics (CFD) is a numerical simulation technique used to simulate fluid flow and heat transfer in complex systems. CFD involves dividing a fluid into small, discrete elements and then solving equations that describe the behavior of each element. CFD is widely used in the aerospace, automotive, and energy industries to optimize the design of airfoils, combustion chambers, and other fluid-related components.

What is the discrete element method (DEM)?

Discrete Element Method (DEM) is a numerical simulation method used to model the behavior of granular materials such as powders, grains, and minerals such as rocks, ores, and coal. DEM involves simulating the interactions between individual particles, taking into account factors such as particle size, shape, and friction. DEM is widely used in the mining, pharmaceutical, and food processing industries to optimize the design of handling and processing equipment.

What is testing, and how is it used in engineering design?

Testing a prototype or developed design to measure their behavior under different conditions is as important as the design and manufacturing processes. Thorough testing and evaluation are crucial steps of numerical simulations, helping to ensure the viability of a product, compliance with applicable regulations, and providing empirical data that can be used to validate simulation models and identify critical areas for improvement. Testing simulations include durability, fatigue, vibration, drop testing, mechanical and electrical testing, and others.

4. What industries use numerical simulation in their engineering design workflows?

As mentioned earlier, numerical simulation is used in a wide range of industries for a wide range of use cases. From aerospace to automotive to medical devices to consumer products and beyond, numerical simulation has become an essential tool for ensuring product performance, reliability, and safety.

For instance, numerical simulation is widely used in the powersports industry, including the development of motorcycles, ATVs, snowmobiles, and other off-road vehicles. One example of the use of numerical simulation in powersports is the development of motorcycle engines. To achieve optimal engine performance, engineers must ensure that the engine is designed to withstand the stresses and strains it will experience during operation. By using simulation software, engineers can create virtual prototypes of the engine and subject it to a variety of conditions, such as different engine speeds and loads, to determine its durability, reliability, and performance.

Source: https://creaform-engineering.com/en/solutions-industry/powersports/

Another example is the design of suspension systems for off-road vehicles such as ATVs and side-by-sides. Suspension systems must be designed to handle a variety of terrains and loads, provide a comfortable ride for the driver and passengers, and ensure safety. By using simulation software, engineers can evaluate different suspension configurations and optimize their design to meet these requirements.

Numerical simulation is also widely used in the defense and marine industries to simulate ship motion and loads on ships and offshore structures. Using specialized software, engineers model and analyze different scenarios, such as how a ship would behave in different sea states, how loads would affect the structure, and how the ship would respond to different environmental conditions. Marine and shipbuilding companies also use numerical simulations such as CFD to analyze and prevent liquefied natural gas leaks.

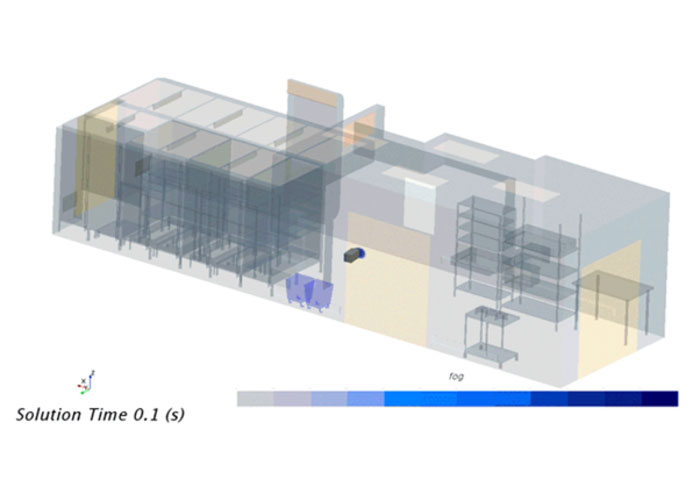

Source: https://creaform-engineering.com/en/portfolio-items/analysis-of-lng-tank-holding-room/

Last but not least, numerical simulation is used to optimize the performance of electric and hybrid electric vehicles, including the design of the battery systems, motor and power electronics systems, and charging infrastructure widely used in the transportation industry. It is also used to simulate the behavior of electric vehicles under different driving conditions and to optimize energy management systems.

5. What are the advantages of numerical simulation?

Numerical simulation offers several advantages over traditional design methods such as physical prototyping, trial-and-error testing, or hand calculations.

More cost-efficient and faster product development

Physical product development involves building a physical prototype and then taking it to the lab for testing. Once tested, various design flaws are revealed that would require redesign or even reconfiguration, extending the development timeline.

Unlike the trial-and-error approach, numerical simulation doesn't require a physical prototype. All testing and analysis can be done virtually, in much broader and more diverse operating conditions and environments that are not always available on-site. This significantly reduces the need for repetitive, time-consuming testing on expensive physical prototypes, thereby reducing the overall time and cost of the product development process.

Enhanced product quality and performance

Although faster product development doesn’t always result in better quality and performance, it actually does in the case of numerical simulation. By identifying potential defects and failures early in the design process through virtual prototyping, product and system designers can come up with better, smarter, and more efficient design solutions, improving the quality of the final product.

The same goes for product performance. Since numerical simulation makes it possible to evaluate the impact of different design variables on product performance, such as material selection, geometry, and operating conditions, it helps engineers optimize overall product performance and resources used in the process.

Single-prototype product development

Numerical simulation not only makes prototyping and product development faster but also reduces the number of prototypes to test, analyze, and validate, to begin with. In many cases, thanks to advances in simulation software, there can be only one prototype needed to make the product right the first time.

Unlike physical prototypes, simulation models offer greater flexibility and provide analytical results that might be impossible to obtain through physical testing. An engineer or product designer can create a virtual prototype from scratch using a wide range of 3D CAD software or scan an actual product with professional-grade 3D scanners and then modify it without having to work with an actual physical unit.

Since there is no damage risk or material waste, they can put simulation models in a far wider range of operational conditions, set the most extreme boundaries, and virtually test areas of the product that cannot be physically accessed. If done properly, a company may only need one physical prototype unit, the final product, for an actual “test drive” before going into mass production.

Resource optimization and reduced energy consumption

Physical prototyping typically requires building or sourcing materials and parts, and then assembling them for design and performance testing and evaluation in real-world scenarios, all of which require significant time and resources. Numerical simulation makes the entire process more affordable and flexible in terms of resources and energy.

It requires fewer designers and engineers to do the work and far fewer resources to set up the simulation environment and boundary conditions, all of which can be controlled by specialized software. This all adds up to enough time, effort, money, and energy savings that the company can spend more productively on further research, product design, and development. It also makes the whole process more environmentally friendly by reducing material waste and energy consumption.

Increased safety and compliance

Numerical simulation can also help increase the safety of products and systems by identifying potential hazards and assessing how a design responds to those hazards. For instance, in the automotive industry, crash simulations are performed to evaluate the impact of collisions on the car and its occupants and to optimize the design of safety features such as airbags, seat belts, and crumple zones.

Numerical simulation can also help ensure compliance with industry standards by allowing engineers and designers to evaluate designs against regulatory requirements before any physical prototyping or testing takes place. This helps to identify potential compliance issues early in the design process and allows for corrections to be made before any significant resources are invested in physical prototypes or testing. For example, simulations can be used to evaluate the crashworthiness of a vehicle's design, including how it will perform in various types of crashes and collisions. This helps to ensure that the vehicle meets safety standards set by regulatory bodies like the National Highway Traffic Safety Administration (NHTSA) and the European New Car Assessment Programme (Euro NCAP).

Optimized manufacturing processes

As mentioned earlier, numerical simulation is not limited to evaluating product performance but is also effective in determining the best possible manufacturing process. Simulation of manufacturing processes is commonly referred to as "virtual manufacturing" and includes simulation of processes such as forming, stamping, and machining, as well as the production line environment and equipment involved.

By virtually simulating the manufacturing processes, manufacturers can determine the manufacturability of the design and whether the product idea is technically feasible and will be profitable with the resources allocated and the quality expected. For example, depending on the complexity of the design, the manufacturer can make an informed decision about whether to abandon the idea or invest in more advanced equipment. Overall, the ability to view a simulation of the manufacturing process while designing the product results in optimized manufacturing processes and products optimized for performance, quality, and cost.

Conclusion

As Industry 4.0 continues to reshape the manufacturing industry, simulation-driven design has become an increasingly important tool for manufacturers looking to improve their product development processes and remain competitive in today's fast-paced economy.

With so many simulation techniques and software tools available today, it's a must-have process that, when implemented properly, can result in reduced material costs, optimized product performance, safety, and usability, as well as reduced time and resources required for the design process.

Share This Story, Choose Your Platform!